BONDING WIRE

Bonding Wire

Bonding wire is a critical component used in the semiconductor industry for connecting a semiconductor die to its package. It provides an electrical and mechanical connection between the die and the leads of the package. Bonding wires are typically made of gold, aluminum, or copper.

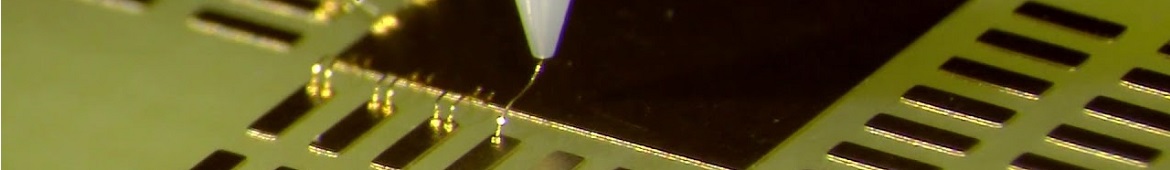

The bonding process involves creating a wire bond between the die and the lead frame or substrate using a wire bonding machine. The machine first creates a small ball at the end of the wire, which is then placed on a bond pad on the die. The machine then uses heat, pressure, and ultrasonic energy to bond the wire to the pad. The other end of the wire is then bonded to the lead frame or substrate.

- Gold bonding wire is the most commonly used type of wire in the semiconductor industry. It offers excellent electrical conductivity, good thermal conductivity, and high reliability. It is commonly used in high-performance devices that require a long lifespan and a high level of reliability, such as automotive and aerospace applications.

- Silver (Ag) bonding wire is a type of wire used in the semiconductor industry for wire bonding applications, where it offers high electrical conductivity and good thermal conductivity.

- Aluminum bonding wire is a more cost-effective alternative to gold wire. It has a lower melting point and lower electrical conductivity than gold, but it is still widely used in consumer electronics and other applications that do not require high reliability.

- Copper bonding wire is a relatively new type of wire that offers high electrical conductivity, high thermal conductivity, and low resistance. It is commonly used in high-performance devices that require high-speed data transfer and low power consumption.

In summary, bonding wire is a crucial component of semiconductor packaging, providing the electrical and mechanical connections between the die and the package. The choice of bonding wire material can significantly impact the performance, reliability, and cost of the final product.

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com