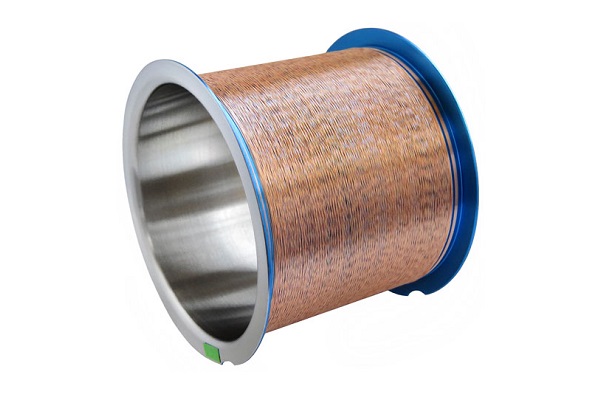

Copper (Cu) Bonding Wire

Copper (Cu) Bonding Wire

Description

Copper (Cu) bonding wire is a type of wire used in the semiconductor industry for wire bonding applications. It is made from high-purity copper with a purity level of 99.99% or higher, and is available in various diameters ranging from 15 to 75 microns.

The wire bonding process involves using a wire bonding machine to bond the wire to the pads on the surface of a semiconductor device. The machine uses heat and pressure to create a metallic bond between the wire and the pad.

Copper bonding wire offers several advantages over other bonding materials, including high electrical conductivity, good thermal conductivity, and lower cost compared to gold or silver wire. Additionally, copper wire has a higher tensile strength than gold wire.

However, copper bonding wire also has some disadvantages, such as susceptibility to oxidation and lower reliability due to the formation of copper oxide during wire bonding. This can lead to issues such as reduced bond strength and increased wire resistance.

To overcome these challenges, manufacturers have developed various methods to mitigate the oxidation of copper wire during the bonding process. These methods include using an anti-oxidation layer on the surface of the wire or using a reducing atmosphere during the bonding process.

Overall, copper bonding wire is a widely used material in the semiconductor industry due to its high conductivity and lower cost compared to gold or silver wire. However, its use requires careful consideration of potential oxidation issues and proper mitigation methods to ensure optimal bonding performance and reliability.

Palladium (Pd) Coated Copper (4N Cu) with Gold (Au) Flash Bonding Wire

| Ø Diameter ±1% μm | Breaking Load (gf) | Breaking Load (mN) | El (%) | Length Meters | Length Feet |

| Ø 15µm (Ø 0.6 mil) | 2.0~5.0 gf | 20~49 mN | 3.0~13.0% | 100m 300m 1000m | 300ft 1000ft 3000ft |

| Ø 18µm (Ø 0.7 mil) | 3.2~7.2 gf | 31~71 mN | 5.0~15.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 20µm (Ø 0.8 mil) | 4.0~8.9 gf | 39~87 mN | 5.0~15.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 25µm (Ø 1.0 mil) | 6.3~14.0 gf | 62~137 mN | 5.0~15.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 30µm (Ø 1.2 mil) | 9.1~20.2 gf | 88~198 mN | 7.0~20.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 32µm (Ø 1.25 mil) | 10.3~22.9 gf | 101~225 mN | 7.0~20.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 38µm (Ø 1.5 mil) | 14.4~32.2 gf | 141~316 mN | 7.0~20.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 50µm (Ø 2.0 mil) | 29.2~60.4 gf | 286~592 mN | 10.0~25.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

Copper (2N Cu) Alloy Bonding Wire

| Ø Diameter ±1% μm | Breaking Load (gf) | Breaking Load (mN) | El (%) | Length Meters | Length Feet |

| Ø 15µm (Ø 0.6 mil) | 2.4~5.4 gf | 23~53 mN | 7.0~17.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 18µm (Ø 0.7 mil) | 3.4~7.6 gf | 33~75 mN | 7.0~17.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 20µm (Ø 0.8 mil) | 4.2~9.5 gf | 41~93 mN | 7.0~17.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 25µm (Ø 1.0 mil) | 6.5~14.5 gf | 64~143 mN | 8.0~20.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 32µm (Ø 1.25 mil) | 10.9~24.4 gf | 107~239 mN | 9.0~22.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 38µm (Ø 1.5 mil) | 15.2~33.9 gf | 149~332 mN | 9.0~22.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 50µm (Ø 2.0 mil) | 28.5~59.9 gf | 279~587 mN | 12.0~27.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 60µm (Ø 2.4 mil) | 41.0~86.2 gf | 402~845 mN | 12.0~27.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 70µm (Ø 2.8 mil) | 55.8~117.4 gf | 547~1151 mN | 12.0~27.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

4N Copper (Cu) Bonding Wire

| Ø Diameter ±1% μm | Breaking Load (gf) | Breaking Load (mN) | El (%) | Length Meters | Length Feet |

| Ø 18µm (Ø 0.7 mil) | 3.6~7.8 gf | 35~76 mN | 7.0~17.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 20µm (Ø 0.8 mil) | 4.4~9.6 gf | 43~94 mN | 7.0~17.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 25µm (Ø 1.0 mil) | 6.8~14.8 gf | 67~145 mN | 8.0~20.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 32µm (Ø 1.25 mil) | 11.3~24.8 gf | 111~243 mN | 12.0~24.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 38µm (Ø 1.5 mil) | 15.8~34.5 gf | 155~338 mN | 12.0~24.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 50µm (Ø 2.0 mil) | 26.5~57.9 gf | 260~568 mN | 14.0~26.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 60µm (Ø 2.4 mil) | 38.2~83.4 gf | 375~818 mN | 14.0~26.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

| Ø 70µm (Ø 2.8 mil) | 52.0~113.5 gf | 510~1131 mN | 14.0~26.0% | 100m 300m 500m | 300ft 1000ft 1500ft |

Copper (Cu) Heavy Power Bonding Wire

| Ø Diameter ±7% μm | Breaking Load (gf) | Breaking Load (N) | El (%) | Length Meters | Length Feet |

| Ø 100µm (Ø 4 mil) | 102~305 gf | 1.0~3.0 N | 5~35% | 100m | 300ft |

| Ø 125µm (Ø 5 mil) | 153~356 gf | 1.5~3.5 N | 5~35% | 100m | 300ft |

| Ø 150µm (Ø 6 mil) | 255~560gf | 2.5~5.5 N | 5~35% | 100m | 300ft |

| Ø 200µm (Ø 8 mil) | 510~917 gf | 5.0~9.0 N | 5~35% | 100m | 300ft |

| Ø 250µm (Ø 10 mil) | 816~1427 gf | 8.0~14.0 N | 5~35% | 100m | 300ft |

| Ø 300µm (Ø 12 mil) | 1326~2039 gf | 13.0~20.0 N | 5~35% | 100m | 300ft |

| Ø 380µm (Ø 15 mil) | 2040~3059 gf | 20.0~30.0 N | 10~40% | 100m | 300ft |

| Ø 400µm (Ø 16 mil) | 2346~3365 gf | 23.0~33.0 N | 10~40% | 100m | 300ft |

| Ø 500µm (Ø 20 mil) | 4079~5302 gf | 40.0~52.0 N | 10~50% | 100m | 300ft |

Copper (Cu) Bonding Ribbon

| Width | Thickness | Breaking Load (gf) | Breaking Load (N) | El (%) | Length Meters | Length Feet |

| 500µm ±50µm | 100µm ±10µm | Call | Call | ≥10% | 100m 200m | 300ft 600ft |

| 1000µm ±100µm | Call | Call | ≥10% | 100m 200m | 300ft 600ft | |

| 1500µm ±150µm | Call | Call | ≥10% | 100m 200m | 300ft 600ft | |

| 2000µm ±200µm | Call | Call | ≥10% | 100m 200m | 300ft 600ft | |

| 1000µm ±100µm | 150µm ±15µm | Call | Call | ≥10% | 100m | 300ft |

| 1500µm ±150µm | Call | Call | ≥10% | 100m | 300ft | |

| 2000µm ±200µm | Call | Call | ≥10% | 100m | 300ft | |

| 1000µm ±100µm | 200µm ±20µm | Call | Call | ≥10% | 100m | 300ft |

| 1500µm ±150µm | Call | Call | ≥10% | 100m | 300ft | |

| 2000µm ±200µm | Call | Call | ≥10% | 100m | 300ft |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com