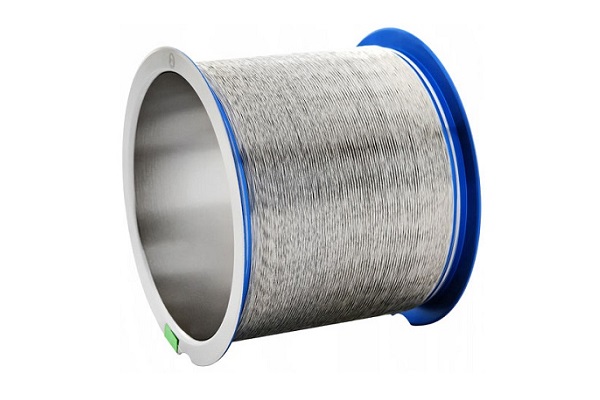

Silver (Ag) Bonding Wire

Silver (Ag) Bonding Wire

Description

Silver (Ag) bonding wire is a type of wire used in the semiconductor industry for wire bonding applications. It is made from high-purity silver with a purity level of 99.99% or higher, and is available in various diameters ranging from 15 to 75 microns.

The wire bonding process involves using a wire bonding machine to bond the wire to the pads on the surface of a semiconductor device. The machine uses heat and pressure to create a metallic bond between the wire and the pad.

Silver bonding wire offers several advantages over other bonding materials, including high electrical conductivity, good thermal conductivity, and excellent bonding performance. It is also relatively low-cost compared to other high-performance bonding materials such as gold.

However, silver bonding wire also has some disadvantages, such as susceptibility to oxidation and lower mechanical strength compared to gold wire. It is therefore typically used in applications where high electrical and thermal conductivity are critical, but where cost is a primary consideration.

Overall, silver bonding wire is a widely used and important material in the semiconductor industry, offering high performance and cost-effectiveness for certain applications.

| Ø Diameter ±1% μm | Breaking Load (gf) | Breaking Load (mN) | El (%) | Length Meters | Length Feet |

| Ø 15µm (Ø 0.6 mil) | 2.8~5.6 gf | 27~55 mN | 1.0~8.0% | 300m 500m | 1000ft 1500ft |

| Ø 18µm (Ø 0.7 mil) | 4.1~8.0 gf | 40~78 mN | 1.0~8.0% | 300m 500m | 1000ft 1500ft |

| Ø 20µm (Ø 0.8 mil) | 5.1~10.0 gf | 50~98 mN | 1.0~8.0% | 300m 500m | 1000ft 1500ft |

| Ø 25µm (Ø 1.0 mil) | 7.8~15.4 gf | 78~151 mN | 1.0~8.0% | 300m 500m | 1000ft 1500ft |

| Ø 30µm (Ø 1.20 mil) | 11.1~21.9 gf | 109~215 mN | 1.0~10.0% | 300m 500m | 1000ft 1500ft |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com