DIE ATTACH ADHESIVE

DIE ATTACH ADHESIVE

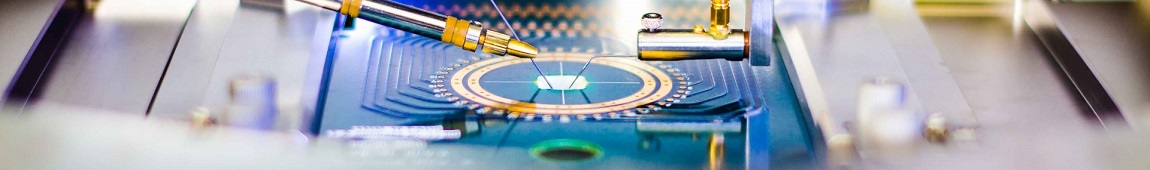

Die attach adhesive is a type of adhesive material that is used to attach semiconductor dies or chips to a substrate, such as a printed circuit board (PCB). The adhesive plays a critical role in the assembly process of electronic devices, ensuring that the die is securely and reliably attached to the substrate.

The die attach adhesive typically consists of a thermosetting epoxy resin that is filled with conductive or non-conductive materials, depending on the specific requirements of the application. The adhesive is dispensed onto the substrate, and the die is placed on top of the adhesive. The adhesive is then cured, either through heat or UV light, which causes it to harden and create a strong bond between the die and the substrate.

Die attach adhesives are available in a variety of formulations to meet the specific needs of different applications. For example, some adhesives are designed to provide high thermal conductivity to help dissipate heat generated by the die, while others are designed to provide high electrical conductivity to allow for better electrical performance.

The choice of die attach adhesive is critical to the overall reliability and performance of the electronic device. Factors such as the size and weight of the die, the thermal and electrical requirements of the application, and the bonding process used all play a role in determining the appropriate die attach adhesive to use.

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com