Die-Attach Paste Adhesives

Die-Attach Paste Adhesives

Description

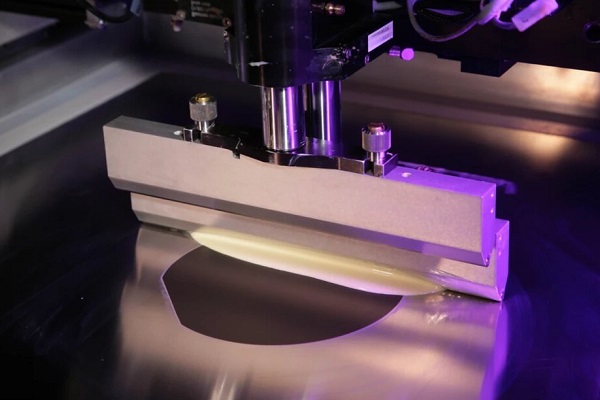

Die-attach paste adhesive is a type of adhesive material that is commonly used in the assembly of semiconductor devices. It is a viscous, paste-like material that is dispensed onto the substrate, and then the die is placed on top of the paste. The adhesive is then cured, typically through heat, which causes it to harden and create a strong bond between the die and the substrate.

Die-attach paste adhesive is typically made from a mixture of polymer resins, filler materials, and curing agents. The specific composition of the adhesive will depend on the requirements of the application, such as the size and weight of the die, the thermal and electrical properties required, and the bonding process used.

One advantage of using die-attach paste adhesive is that it can be dispensed with high precision, allowing for tight control over the amount and distribution of the adhesive. This can help to ensure that the die is securely attached to the substrate and that any voids or gaps in the bond line are minimized.

Die-attach paste adhesive is commonly used in a variety of semiconductor applications, including power electronics, LED packaging, and microelectronics. It is typically dispensed using automated equipment, such as dispensing robots or stencil printers, to ensure consistent and repeatable results.

| Characteristics | Electrical Resistivity (ohm-cm) | Thermal Conductivity(watt/m-°C) | Die-shear(psi) | Tg (°C) | Viscosity/ Thixotropic IndeX |

|---|---|---|---|---|---|

One or two part component | <4x10-4 | >5.7 | >1,800 | 50 | 150,000(cps@ 0.5 rpm) |

Solder replacement- Stress free-Substrate/component | <4x10-4 | >7.9 | >1,500 | -20 | 129,000(cps@ 0.5 rpm) |

Solder replacement Stress free | <4x10-4 | >7.9 | >2,000 | -20 | 190,000(cps@ 0.5 rpm) |

Stress free Solvent free | <4x10-4 | >7.9 | >2,000 | -20 | 354,000(cps@ 0.5 rpm) |

Stress free Solvent free Large area die attach | <4x10-4 | >7.9 | >2,000 | -20 | 255,000(cps@ 0.5 rpm) |

Stress free Large area die attach | <4x10-4 | >7.9 | >1,000 | -20 | 130,000(cps@ 0.5 rpm) |

Ideal for mismatched CTE’s | <4x10-4 | >12.5 | >1,200 | -20 | 60,000(cps@ 0.5 rpm) |

Solvent free Designed to eliminate bleeding | <4x10-4 | >7.9 | >1,200 | 50 | 15,000(cps@ 0.5 rpm) |

High green strength Moisture resistant | <1x10-3 | >7.9 | >1,000 | -55 | 40,000(cps@ 5 rpm) |

Solvent free Fine pitch Rapid curing | <4x10-4 | >8.6 | >2,400 | 80 | 8,000(cps@ 5 rpm) TI >4.0 |

Solvent free Fine pitch Rapid curing for inline process | <5x10-4 | >8.6 | >2,400 | 80 | 15,000(cps@ 5 rpm) TI >4.0 |

Solvent free Fine pitch Rapid curing | <4x10-4 | >3.6 | >1,900 | -40 | 8,000(cps@ 5 rpm) TI >4.0 |

Solvent free Fine pitch Rapid curing for inline process | <5x10-4 | >7.9 | >1,500 | -20/-50 Minor | 18,000(cps@ 5 rpm) TI >4.0 |

Stress free High Green Strength | <5x10-4 | >7.9 | >1,000 | -20/-50 minor | 10,000(cps@ 5 rpm) |

Solvent free Withstands 350 Deg C Low Moisture Absorption Low Ionics | <5x10-2 | >9 | >2,500 | 240 | 65,000(cps@ 5 rpm) |

| Characteristics | Electrical Resistivity(ohm-cm) | Thermal Conductivity(watt/m-°C) | Die-shear (psi) | Tg (°C) | Viscosity |

|---|---|---|---|---|---|

Stress free One or two component Large bonding areas | >1x1014 | >1.7 | >1,800 | -20 | 300,000(cps@ 0.5 rpm) |

Substrate attach Large bonding areas Bonding mismatched CTE’s | >1x1014 | >3.67 | >1,800 | -25 | 337,000(cps@ 0.5 rpm) |

Solvent free Stress free | >1x1014 | >1.7 | >1,800 | -25 | 275,000(cps@ 0.5 rpm) |

Solvent free Stress free | >1x1014 | >3.6 | >1,800 | -25 | 245,000(cps@ 0.5 rpm) |

Stress free Mismatched CTE’s | >1x1014 | >1.7 | >2,400 | -25 | 144,000(cps@ 0.5 rpm) |

Stress free High power die attach | >1x1014 | >3.6 | >1,800 | -25 | 250,000(cps@ 0.5 rpm) |

Stress free Diamond filled | >1x1014 | >11.4 | >1,800 | -25 | 310,000(cps@ 0.5 rpm) |

Solvent free Rapid inline curing More than 7 days pot-life | >1x1014 | >1.2 | >3,200 | 60 | 38,000(cps@ 5 rpm) TI >3.0 |

Solvent free Rapid inline curing More than 7 days pot-life | >1x1014 | >0.86 | >1,200 | -25 | 50,000(cps@ 5 rpm) TI >3.0 |

Stress free Fast curing | >1x1014 | >3.6 | >1,200 | -10 | 200,000(cps@ 0.5 rpm) |

Solvent free Low temperature curing | >1x1014 | >1.7 | >2,000 | 80 | 20,000(cps@ 5 rpm) |

Solvent free High Green Strength | >1x1013 | >2.9 | >1,500 | -60 | 60,000(cps@ 5 rpm) |

Solvent free Withstands 350 Deg C Low Moisture Absorption Low Ionics | NA | >1.0 | >2,500 | 240 | 65,000(cps@ 5 rpm) |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com