ENCAPSULATION MATERIALS

Encapsulation Materials

Description

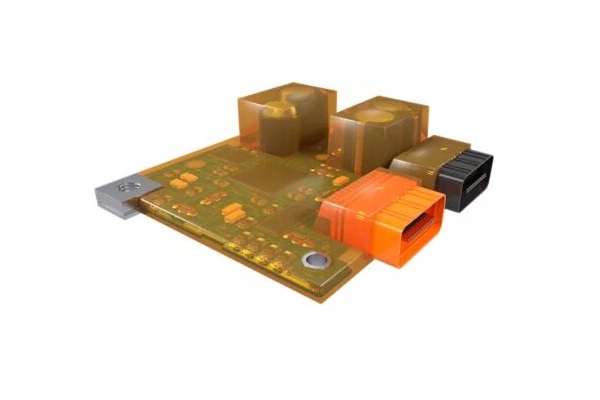

Encapsulation materials in the semiconductor industry are used to protect and insulate the semiconductor devices from external environmental factors and physical damage. These materials are typically applied in liquid or solid form, and then cured or hardened to form a protective layer around the device.

The most commonly used encapsulation materials in the semiconductor industry include epoxy resins, silicone rubber, and polyimide. These materials offer various benefits such as high mechanical strength, chemical resistance, and excellent electrical insulation properties.

Epoxy resins are widely used for encapsulation due to their high adhesion, strength, and thermal stability. They can also be easily modified to meet specific performance requirements.

Silicone rubber is another popular encapsulation material that offers good flexibility, high temperature resistance, and good resistance to moisture and chemicals. It is also known for its excellent electrical insulation properties.

Polyimide is a high-performance encapsulation material that offers high thermal stability, low dielectric constant, and excellent mechanical strength. It is commonly used in high-temperature applications and for flexible printed circuits.

Other types of encapsulation materials used in the semiconductor industry include acrylates, polyurethanes, and parylene. These materials offer unique properties such as high optical clarity, flexibility, and biocompatibility.

Overall, encapsulation materials play a critical role in protecting semiconductor devices from external environmental factors and physical damage. The selection of the appropriate encapsulation material is dependent on the specific performance requirements and environmental conditions of the application.

| Description | Melt-Flow, Curing, Process Conditions | Modulus (GPa) | CTE (ppm/°C) | Tg (°C) | Dielectric Constant/Loss (1MHz) | Ionic Impurities (Na+, K+, Cl-, etc.) |

|---|---|---|---|---|---|---|

| Quartz filled Semi-solid mixture Ultra low CTE | Injection or transfer @40-60°C Curing @ 175°C/10 sec | 8.0 | 16 | 236 | 3.8/0.01 | < 10 ppm |

| Alumina filled Semi-solid mixture Thermally conductive | Injection or transfer @40-60°C Curing @ 175°C/10 sec | 8.0 | 18 | 236 | 4.2/0.01 | < 10 ppm |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com