Compressible Phase-Change Thermal Interface Pads

Compressible Phase-Change Thermal Interface Pads

Description

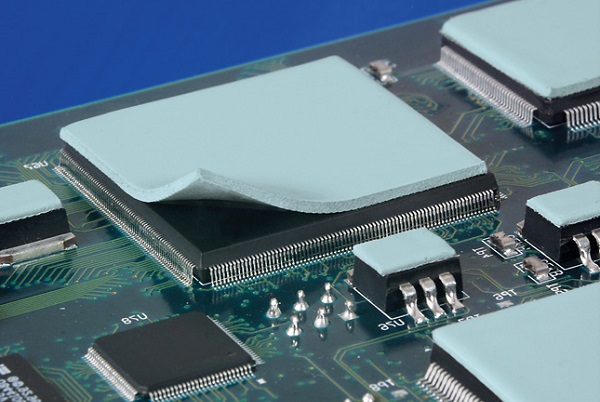

Compressible phase-change thermal interface pads (TCPs) are a type of thermal interface material (TIM) used in the semiconductor industry to improve the heat dissipation performance of electronic devices.

TCPs consist of a compressible polymer material infused with a phase-change material (PCM), such as a wax or a gel. The PCM undergoes a phase change from a solid to a liquid state when exposed to heat, which helps to fill any gaps or voids between the heat source and the heat sink, improving the thermal conductivity of the interface.

When pressure is applied to a TCP, the material compresses and conforms to the surfaces of the heat source and heat sink, maximizing contact and minimizing air gaps that can act as insulators. The PCM in the TCP melts and fills any remaining gaps or voids, further improving the thermal conductivity of the interface.

TCPs offer several benefits in the semiconductor industry, including high thermal conductivity, low thermal resistance, and the ability to conform to non-flat or irregular surfaces. They also provide a reliable and consistent thermal interface, even under conditions of high temperature and mechanical stress.

The selection of the appropriate TCP is dependent on various factors such as the specific electronic device, the power density and operating temperature of the device, and the manufacturing process. Manufacturers offer a wide range of TCPs with different thermal performance, compressibility, and thickness to suit different applications.

Compressible phase-change thermal interface pads play a critical role in improving the thermal management performance of electronic devices, ensuring that they operate effectively and efficiently while minimizing the risk of thermal failure.

| Characteristics | Electrical Resistivity (ohm-cm) | Thermal Conductivity(watt/m-°C) | Dielectric Strength (volt/mil) | Die-shear (psi) | Tg (°C) |

|---|---|---|---|---|---|

| -In-situ curing >60°C -Flexible to -55°C | >1×1014 | >2.0 | >550 | >600 | -55 |

| -In-situ curing >60°C -Flexible to -55°C | >1×1014 | >4.0 | >550 | >600 | -55 |

| -High Melt-Flow >135°C -Flexible to-55°C | >1×1014 | >2.0 | >550 | >800 | -55 |

| -High Melt-Flow >135°C -Flexible to -55°C | >1×1014 | 4.0 | >550 | >600 | -55 |

| -In-situ curing -Pressure Sensitive | >1×1014 | 3.6 | 750 | >600 | -25 |

| -In-situ curing >60°C -100 psi die-shear as applied | >1×1014 | >3.6 | 750 | >600 | -25 |

| -In-situ curing >60°C -50 psi die-shear as applied | >1×1014 | >1.9 | 750 | >300 | -25 |

| -Non-curing -Compressible phase-change pad | >1×1014 | >3.0 | 550 | NA | -45 |

| -Non-curing -Compressible phase-change pad | >1×1014 | >2.0 | 550 | >600 | -45 |

| -Melt-Flow @ 65°C -Power Device to Heat-sink | >1×1014 | 2.0 | >6000 | NA | -55 |

| -Melt-Flow @ 50°C -Low Bond Strength | >1×1014 | 4.0 | 550 | <100 | -55 |

| -Melt-Flow @ >70°C -Aluminum Nitride filled Dry Film | >1×1014 | 4.0 | >550 | <300 | -55 |

| -High Melt-Flow @ >135°C -Aluminum Nitride filled Dry Film | >1×1014 | >4.0 | >550 | <900 | -55 |

| -High Melt-Flow @ >135°C -Aluminum Oxide filled Dry Film | >1×1014 | 2.0 | >550 | >800 | -55 |

| -High Melt-Flow @ >135°C -Kapton lined | >1×1014 | 2.0 | >5000 | >800 | -55 |

| -High Melt-Flow @ >150°C -Aluminum Nitride filled Dry Film | >1×1014 | 4.0 | >550 | >700 | -55 |

| -High Melt-Flow @ >135°C -Kapton lined | >1×1014 | 4.0 | >3000 | >800 | -55 |

| -Puncture Resistant Pad ->1500V Insulation @ 3 mil -Polyimide laminates availible | >1×1014 | 1.8 | >750 | NA | -55 |

| -Non-curing -Non-flowing -Thermal gasket pad -Polyimide laminates availible | >1×1014 | >3.0 | 550 | NA | -45 |

| -Melt-Flow @ 55°C -Aluminum Oxide Filled Dry Pad | >1×1014 | 1.8 | >550 | <40 | -55 |

| -High Flow @ 50°C -One side Tacky film | >1×1014 | 4.0 | >550 | <100 | -55 |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com