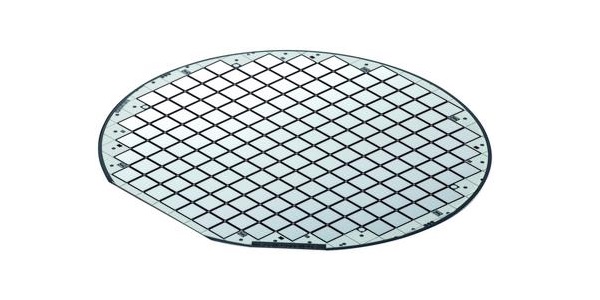

STD Glass Passivated Pellet (GPP) Rectifier Diode Chips

Description

Glass Passivated Pellet (GPP) rectifier diode chips are a type of semiconductor device that is commonly used in electronic circuits to convert alternating current (AC) to direct current (DC). GPP rectifiers are made of a pellet-shaped silicon wafer that is coated with a layer of glass to protect it from contaminants and oxidation.

The glass passivation layer on the surface of the diode chip serves as a protective barrier to prevent the underlying silicon from reacting with oxygen or other impurities in the environment. This layer also helps to improve the diode's performance by reducing the surface recombination of charge carriers.

GPP rectifier diode chips have several advantages over other types of rectifiers, including high efficiency, low forward voltage drop, and low reverse leakage current. These features make them ideal for use in power supplies, battery chargers, and other high-performance applications where low power dissipation and high reliability are critical.

| Die Size | VRRM(V) | IF(A) | IFSM(A) | VF(V) | IR(mA) | TJ(℃) | trr(ns) |

| 46 | 200 | 1 | 40 | 0.875 | 2 | 150 | 35 |

| 46 | 400 | 1 | 40 | 1.2 | 2 | 150 | 35 |

| 46 | 600 | 1 | 40 | 1.67 | 2 | 150 | 50 |

| 50 | 200 | 2 | 50 | 0.93 | 2 | 150 | 35 |

| 50 | 400 | 2 | 50 | 1.15 | 2 | 150 | 35 |

| 50 | 600 | 1 | 50 | 1.22 | 2 | 150 | 50 |

| 50 | 800 | 2 | 50 | 1.67 | 2 | 150 | 70 |

| 58 | 200 | 3 | 65 | 0.94 | 2 | 150 | 35 |

| 58 | 200 | 2 | 65 | 0.94 | 2 | 150 | 35 |

| 58 | 600 | 3 | 65 | 0.94 | 2 | 150 | 50 |

| 65 | 200 | 5 | 80 | 0.98 | 2 | 150 | 35 |

| 65 | 200 | 3 | 80 | 0.9 | 2 | 150 | 35 |

| 65 | 400 | 5 | 80 | 1.2 | 2 | 150 | 35 |

| 65 | 400 | 5 | 80 | 1.2 | 2 | 150 | 35 |

| 65 | 600 | 5 | 80 | 1.65 | 2 | 150 | 50 |

| 65 | 600 | 4 | 80 | 1.45 | 2 | 150 | 50 |

| 71 | 200 | 5 | 100 | 0.94 | 2 | 150 | 35 |

| 71 | 400 | 5 | 100 | 1.25 | 2 | 150 | 50 |

| 71 | 400 | 5 | 100 | 1.25 | 2 | 150 | 35 |

| 71 | 600 | 8 | 100 | 1.65 | 2 | 150 | 50 |

| 79 | 600 | 6 | 125 | 1.67 | 2 | 150 | 50 |

| 84 | 200 | 8 | 125 | 0.95 | 2 | 150 | 35 |

| 84 | 400 | 10 | 125 | 1.2 | 2 | 150 | 50 |

| 84 | 400 | 10 | 125 | 1.2 | 2 | 150 | 50 |

| 84 | 600 | 8 | 125 | 1.65 | 2 | 150 | 50 |

| 84 | 600 | 8 | 125 | 1.5 | 2 | 150 | 50 |

| 98 | 200 | 8 | 200 | 0.9 | 2 | 150 | 35 |

| 98 | 600 | 8 | 200 | 1.67 | 2 | 150 | 50 |

| 115 | 600 | 20 | 250 | 1.65 | 4 | 150 | 50 |

| 130 | 600 | 15 | 300 | 1.35 | 4 | 150 | 50 |

| 132 | 600 | 15 | 300 | 1.67 | 4 | 150 | 50 |

| 180 | 600 | 50 | 400 | 1.35 | 4 | 150 | 50 |

| 195 | 400 | 50 | 400 | 1.2 | 4 | 150 | 100 |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com