Aluminum Oxide (Al2O3) Ceramic Substrates

Aluminum Oxide (Al2O3) Ceramic Substrates

Description

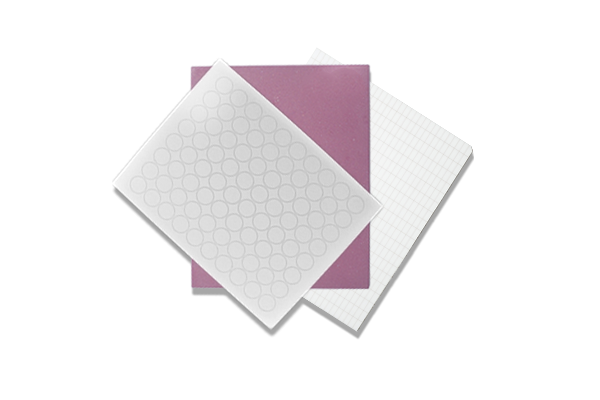

Aluminum Oxide (Al2O3) Ceramic Substrates ceramic substrates are used for hybrid ICs, ceramic capacitors, resistors and other parts for semiconductor and electronics industry. Alumina ceramics are stable to aggressive chemicals like acids and have very good electrical insulation properties and thermal conductivity.

Aluminum oxide (Al2O3) ceramic substrates are a type of ceramic substrate that are commonly used in the electronics industry for their excellent electrical insulation and thermal properties.

Al2O3 ceramic substrates have high thermal conductivity and good electrical insulation properties, making them ideal for use in applications where thermal management is important, such as high-power electronic devices. They also have a high mechanical strength and can withstand harsh environments, such as high temperatures and corrosive environments.

In addition, Al2O3 ceramic substrates have a low dielectric constant and loss tangent, which allows for high-frequency signal transmission with minimal signal loss. This makes them ideal for use in RF/microwave components, such as antennas and filters.

Al2O3 ceramic substrates can be manufactured in various shapes and sizes, such as square, rectangular, and cylindrical, and can be customized to fit specific requirements. They can also be metallized to create conductive paths for electrical signals.

| Properties | Material | |||

| Al 2 O 3 94.4% (VK-94DN) | Al 2 O 3 96.0% (VK-96DN) | Al 2 O 3 99.6% (VK-100DN) | ||

| Colour | pink | White | White | |

| Bulk density | g / cm3 | 3.60 | 3.76 | 3.75 |

| Surface roughness (Ra) | micron | - | 0.2-0.7 | 0.3-0.5 |

| Polished surface roughness (Ra) | micron | - | - | <0.01 |

| Mechanical characteristics | ||||

| Flexural strength | MPa | 280 | 450 | 450 |

| Elastic modulus | GPa | - | 340 | 340 |

| Hardness | kg / mm 2 | - | fourteen | fourteen |

| physical characteristics | ||||

| Thermal expansion coefficient (40-800 ° C) | 10 -6 / ° C | 6.5 - 7.5 | 7.8 | 7.8 |

| Thermal conductivity (25 ° C) | W / m ∙ ° K | 15 - 20 | 25 | 30.7 |

| Specific heat | J / Kg ∙ ° K | - | 750 | 780 |

| Dielectric constant (1 MHz) | - | 9.0 - 10.0 | 9.8 | 9.9 |

| Dielectric loss (1MHz, 25 ° C) | ∙ 10 -4 | 4 | 3 | 3 |

| Technological characteristics | ||||

| DBC technology | X | X | X | |

| (Cu 127 - 450 μm, protective coatings) | ||||

| Thick film technology | X | X | X | |

| (Ag, Au, Ag-Pd, Ag-Pd-Pt, Ni - from 12 to 100 microns) | ||||

| Thin film technology | X | X | X | |

| (guides on request) | ||||

| Distance between scribing lines, mm | 2.00 ± 0.05 | |||

| Minimum hole diameter, mm | 0.20 ± 0.05 | |||

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com