Aluminum Nitride (ALN) Substrates

Aluminum Nitride (AlN) Substrates

Description

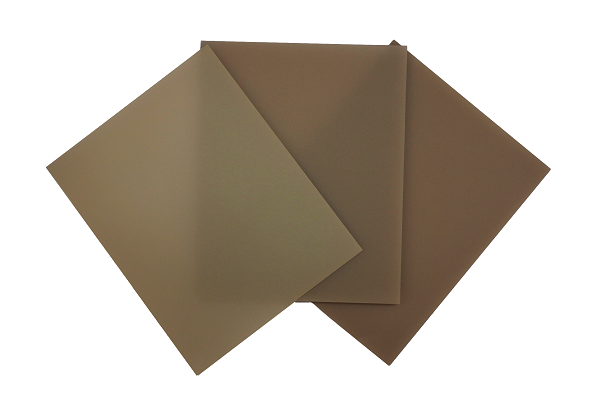

Aluminum nitride (AlN) substrates are a type of ceramic substrate that are used in a variety of applications, including electronics, optics, and power electronics, due to their excellent thermal and electrical properties.

AlN substrates have high thermal conductivity, which makes them effective at dissipating heat generated by electronic components, such as high-power transistors and LEDs. This ability to dissipate heat is critical for the reliability and performance of electronic devices, as excessive heat can cause premature failure of components.

In addition, AlN substrates have a high electrical resistivity and dielectric strength, which make them suitable for use in high-voltage applications. They also have a low coefficient of thermal expansion, which means they maintain their structural integrity at high temperatures, making them ideal for high-temperature applications.

AlN substrates can be manufactured in various sizes and shapes, including square, rectangular, and circular shapes. They can also be metallized to create conductive paths for electrical signals.

AlN substrate is the most frequently used ceramic substrate material for manufacturing electronic components and modules. The main advantage of AlN substrates is high thermal conductivity that can be in the range of 170 to 230W/mK. AlN ceramic is the substrate of choice for devices where high heat dissipation is needed. AlN has high structure purity and chemical uniformity.

The advantages of aluminum nitride are:

- High thermal conductivity;

- Inert to the majority of acids except hot inorganic acids;

- High dielectric strength;

- Compatibility to all metallization technologies.

| Properties | Material | |||

| AlN-170 | AlN-200 | AlN-230 | ||

| Colour | grey | grey | grey | |

| Bulk density | g / cm3 | 3.30 | 3.28 | 3.25 |

| Surface roughness (Ra) | micron | 0.3-0.5 | 0.3-0.5 | 0.3-0.5 |

| Polished surface roughness (Ra) | micron | <0.05 | <0.05 | <0.05 |

| Mechanical characteristics | ||||

| Flexural strength | MPa | 450 | 250 | 200 |

| Elastic modulus | GPa | 320 | 320 | - |

| Hardness | kg / mm 2 | eleven | eleven | - |

| physical characteristics | ||||

| Thermal expansion coefficient (40-800 ° C) | 10 -6 / ° C | 5.4 | 5.4 | 9.0 |

| Thermal conductivity (25 ° C) | W / m ∙ ° K | 180 | 200 | 230 |

| Specific heat | J / Kg ∙ ° K | 720 | 720 | 750 |

| Dielectric constant (1 MHz) | - | 9.0 | 9.0 | 9.8 |

| Dielectric loss (1MHz, 25 ° C) | 10 -4 | 3 | 3 | 3 |

| Technological characteristics | ||||

| DBC technology | X | X | X | |

| (Cu 127 - 450 μm, protective coatings) | ||||

| Thick film technology | X | X | X | |

| (Ag, Au, Ag-Pd, Ag-Pd-Pt, Ni - 12-100 microns) | ||||

| Thin film technology | X | X | X | |

| (guides on request) | ||||

| Distance between scribing lines, mm | 2.00 ± 0.05 | |||

| Minimum hole diameter, mm | 0.20 ± 0.05 | |||

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com