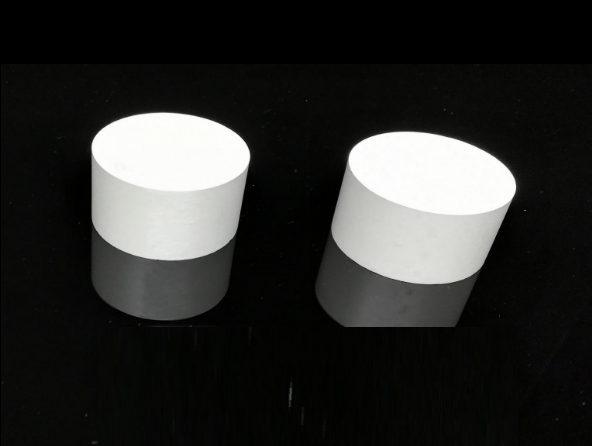

Boron Nitride Blank BN-AN

Boron Nitride Blank BN-AN

Description

Boron Nitride Blank BN-AN is a type of boron nitride material with a polycrystalline structure that is composed of hexagonal boron nitride particles that are fused together. BN-AN is a high-purity, high-strength material that exhibits excellent thermal and electrical insulation properties, high thermal stability, and resistance to thermal shock and chemical attack.

BN-AN can be manufactured using a hot pressing method where hexagonal boron nitride powder is compacted into the desired shape and then heated at high temperatures and pressures to create a dense, polycrystalline structure. The resulting material has a high degree of homogeneity and consistent properties throughout.

BN-AN has many potential applications in high-tech industries, including electronics, aerospace, and energy. In electronics, it can be used as a heat sink material and as a high-temperature insulator. In aerospace, it can be used as a thermal barrier coating for engine components and as a material for rocket nozzles. In energy, it can be used as a filler material in high-temperature composite materials for nuclear reactors and solar cells.

Boron Nitride Blank BN-AN composites by a novel process referred to as transient plastic phase processing (TPPP). The relative density of hot-pressed composites decreased with increasing BN content, but over 99% could be obtained with 30% BN in AlN.BN-AlN gears offer a reliable driving performance under high temperature gas atmospheres in which quartz etc. cannot be used.

Advantages:

● Higher hardness and good wear resistance.

● High mechanical strength and thermal conductivity.

● Used as gears offer a reliable driving performance etc.

Applications:

● Insulator.

● Component for semiconductor equipment.

● Jig material for molding glass.

● Bearing and cogwheel.

| Grade | BN-AN |

| Compositions | BN+AIN |

| Density (g/cm3) | 2.5-2.6 |

| 25°C Volume Resistivity (Ω·cm) | >1014 |

| Max. Service Temp. (°C) | |

| Oxygen | 900 |

| Inert Gas | 2100 |

| High Vacuum | 1900 |

| Flexural Strength (Mpa) | 130 |

| Compressive Strength (Mpa) | 250 |

| Coefficient of Thermal Expansion 25-1000°C (10-6/K) | 4.5 |

| Thermal Conductivity (W/mK) | 60 |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com