Boron Nitride Nozzle BN-SZ

Boron Nitride Nozzle BN-SZ

Description

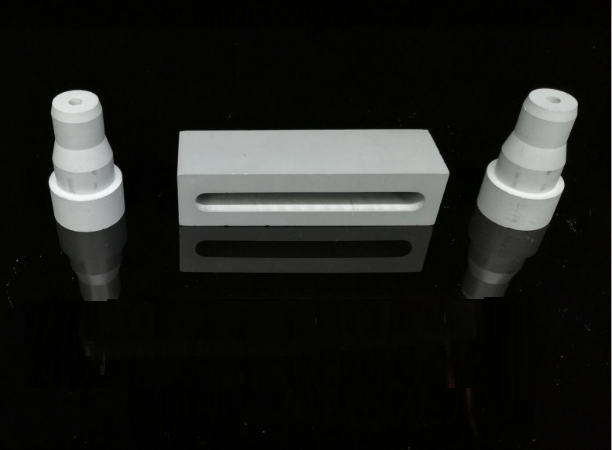

Boron Nitride Nozzle BN-SZ is a type of boron nitride material that is used in various industrial applications as a nozzle material due to its excellent thermal conductivity, high-temperature stability, and good mechanical properties. BN-SZ nozzles are typically made using a hot-pressing method where boron nitride powder is compacted into the desired shape and then heated at high temperatures and pressures to create a dense, polycrystalline structure.

BN-SZ nozzles are used in a wide range of industrial applications, including metal casting, molten metal atomization, and powder spraying. In metal casting, BN-SZ nozzles are used to control the flow of molten metal during the casting process. In atomization, they are used to create fine, uniform droplets of molten metal for powder metallurgy applications. In powder spraying, they are used to direct the flow of powder particles onto a substrate for coatings.

BN-SZ nozzles are preferred over other nozzle materials, such as alumina, because of their superior thermal conductivity and high-temperature stability. Boron nitride has a thermal conductivity that is comparable to that of aluminum, but it can withstand much higher temperatures without degrading. This makes it an ideal material for use in high-temperature applications where other materials may fail.

Boron Nitride Nozzle BN-SZ uses silicon carbide and zirconia binder system. With this system, improve thermal shock resistance and erosion resistibility. Most commonly used as break ring for horizontal continuous casters and nozzles for amorphous thin-strip. Its chemical stability, thermal shock resistance and corrosion resistance properties a wide variety of molten-metal-contact applications.

Advantages:

● Good chemical stability.

● Good erosion resistibility.

● Good thermal shock resistance.

Applications:

● Applications as continuous casting break rings

● Nozzles for metal atomizing and powder metal atomization

● Side dams for thin strip casting

● A variety of molten metal contact applications

| Grade | BN-SZ |

| Compositions | BN+SiC+ZrO2 |

| Density (g/cm3) | 2.3-3.0 |

| 25°C Volume Resistivity (Ω·cm) | >1012 |

| Max. Service Temp. (°C) | |

| Oxygen | 900 |

| Inert Gas | 1700 |

| High Vacuum | 1700 |

| Flexural Strength (Mpa) | 100 |

| Compressive Strength (Mpa) | 300 |

| Coefficient of Thermal Expansion 25-1000°C (10-6/K) | 4.0 |

| Thermal Conductivity (W/mK) | 40 |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com