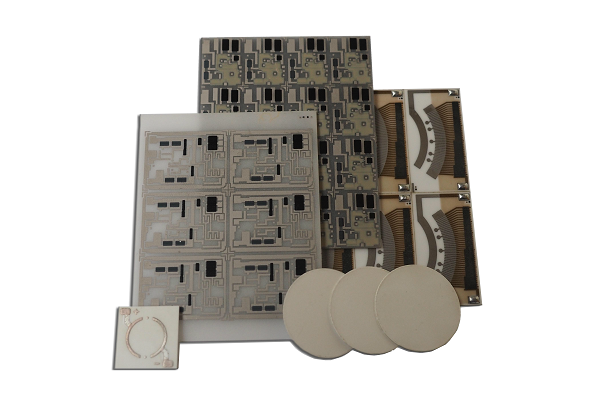

Thick-Film Technology Substrates

Thick-Film Technology Substrates

Description

Thick-film technology substrates are a type of substrate used in electronic devices that rely on thick layers of materials to create circuits and components. Thick-film technology involves depositing a thick layer of a conductive, insulating, or resistive material onto a substrate using a screen printing or other deposition technique.

Thick-film technology substrates are typically made of materials such as alumina, aluminum nitride, or silicon. These materials offer good mechanical stability, thermal conductivity, and chemical resistance, which are essential for the thick-film deposition process and the resulting electronic devices.

Thick-film technology substrates are commonly used in a variety of electronic applications, including sensors, power electronics, and automotive electronics. In these applications, the thick-film layers are used to create circuits, resistors, capacitors, and other components. The use of thick-film technology allows for the creation of complex circuits and components with high precision and reliability.

Thick film technology is widely spread for creating layers for different applications by paste and ceramic substrate sintering. It is a very productive and efficient method allowing to create thick layers from 8um. Thick film technology is applied in:

- thick film hybrid ICs

- thick film active and passive elements

- solar collectors

- many kinds of sensors like pressure, fluid, position etc.

- ionizing radiation sensors

- various inductors

- thermoelectric modules

- solid state relays

- magnet bearings

In this technology conductive, dielectric and semi conductive pastes are used for resistor and capacitor formation. This technology also allows to form thick isolation and protective layers. The pastes are applied with CNC or manual dispenser, screen printing.

| Characteristic | Meaning |

| Resolution (conductor / gap), μm | from 44 to 200 |

| Ceramic used | Al 2 O 3 (VK-94, VK-96), AlN, BeO, etc. |

| Used pastes | resistive, conductive, dielectric, polymer (protective) |

| Paste layer thickness, microns | from 8 to 100 |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com