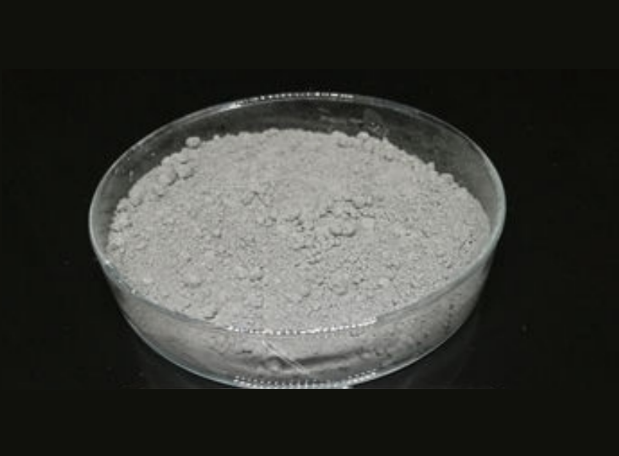

Titanium Diboride Powder

Titanium Diboride Powder

Description

Titanium diboride (TiB2) powder is a ceramic material with a high melting point (approximately 2980°C) and excellent mechanical properties, making it useful in a variety of applications.

TiB2 powder is known for its high hardness, which is comparable to that of diamond. This makes it useful as an abrasive material, and it is often used in cutting tools, grinding wheels, and other abrasive applications.

In addition to its hardness, TiB2 powder is also known for its excellent wear resistance, high strength, and good electrical conductivity. It is often used as a coating material for parts that will be exposed to high temperatures, corrosive environments, or high-stress conditions.

TiB2 powder is also used as a ceramic reinforcement material in metal matrix composites (MMCs) and ceramic matrix composites (CMCs), where it can improve the strength and toughness of the composite material.

TiB2 is a kind of black powder with hexagonal crystal system. It is odorless and its comprehensive property is excellent. It shows perfect heat proof ability, oxidation resistance and conductivity. Its density is 4.50-4.52 g/cm3, melting point is 2,980°C, and hardness is 3,600. The flexural strength of the hot pressed TiB2 parts are 131.3×106 MPa and it shows oxidation-resistance even at 1,100°C. DMCERA® TiB2 is made in 2000 centigrade temperature furnace that has good crystal, low carbon contents, high purity.

Advantages:

● HIP TiB2 Ceramics density ≥ 4.45 g/cm3

● Chemical inert in HCL and HF acid solution

Applications:

● Cutting tools

● Wear resistant material

● Ceramic Target and armor

● Composite ceramic materials.

● Cathode coating in aluminum electrobath.

● Conductive ceramic material, such as evaporation boat.

| Purity | Oxygen | Carbon | Moisture | Particle Size (D50) |

| ≥99.0% | ≤0.5% | ≤0.3% | ≤0.2% | 4-50 micron |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com