LASER ACTIVE CRYSTAL: YLF

LASER ACTIVE CRYSTAL: YLF

Description

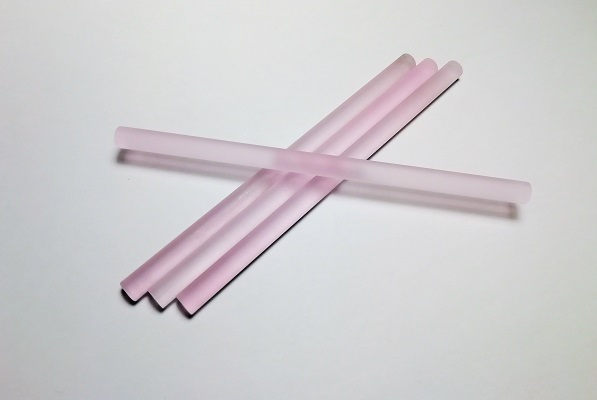

YLF, or yttrium lithium fluoride, is another common laser active crystal used in various laser systems. YLF has a crystalline structure that allows it to amplify light through stimulated emission, similar to YAG.

One of the advantages of YLF as a laser active crystal is its broad emission spectrum, which can be adjusted by doping the crystal with different ions such as neodymium, erbium, or thulium. This makes YLF lasers versatile for different applications that require specific wavelengths.

Nd:YLF, or neodymium-doped YLF, is a popular type of YLF laser. Nd:YLF lasers operate at a wavelength of 1047 nanometers, which is similar to Nd:YAG lasers. However, Nd:YLF lasers have a higher absorption coefficient and a lower thermal conductivity compared to Nd:YAG lasers, which makes them suitable for applications that require a more efficient energy conversion.

Er:YLF, or erbium-doped YLF, is another type of YLF laser that operates at a wavelength of 2.8 micrometers, which is in the mid-infrared region. Er:YLF lasers are commonly used in medical applications, such as dentistry and dermatology, for precise tissue ablation.

| Crystal symmetry | tetragonal |

| Nd dopant concentration, at.% | up to 1.6 |

| Density, g/cm3 | 3.95 |

| Mohs hardness | 4 - 5 |

| Lattice constant, Å | a = 5.26, c = 10.94 |

| Refractive index, at 1.053 µm | no = 1.448; ne = 1.47 |

| Transmission band, µm | 0.1 - 7.5 |

| Thermal conductivity, W x cm-1 x °K-1 | 0.06 |

| Thermal expansion (a), 10-6 x deg C-1 | 13 along a, 8 along c |

| Thermooptical factor (dn/dT), at 1.06 µm | π = 4.3 x 10-6 x °K-1, σ = 2.0 x 10-6 x °K-1 |

| Non-linear index n2, esu | 0.6 x 10-13 |

| Stimulated emission cross-section, cm2 | 3.0 x 10-19 |

| Generated wavelength, µm | π = 1.047, σ = 1.053 |

| Lifetime, µs | 540 |

| Optical losses at 1.053 µm, cm-1 | < 0.003 |

| Optical quality | < 0.3 x 10-5 |

STANDARD SPECIFICATIONS:

| Rod dimensions, mm | dia. (3 - 10) ± 0.1, length (25 - 140) ± 0.2 |

| Rod end face flatness | N = 0.5 interf. band, ΔN = 0.5 interf. band |

| Parallelism of rod end faces, arc.sec | 15 |

| End faces perpendicularity, arc.min | 5 |

| Barrel finish, µm | 1.5 |

| Surface quality | better than 10/5 Scratch/Dig per MIL-O-1380A |

| End faces coating | AR/AR coating |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com