EPITAXIAL WAFERS, THIN FILM WAFERS

EPITAXIAL WAFERS, THIN FILM WAFERS

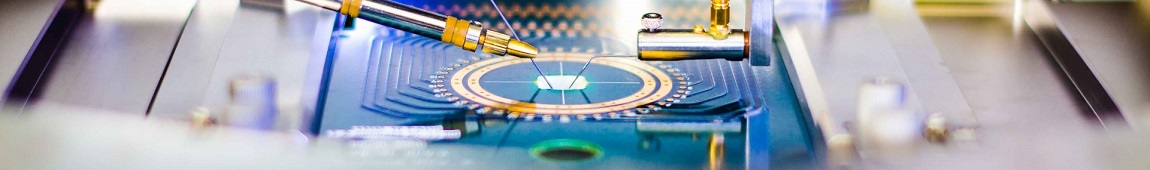

Epitaxial wafers and thin film wafers are both used in the semiconductor industry for the production of electronic devices such as transistors (HEMT), diodes, image sensors (CIS) and integrated circuits (ICs). However, there are some key differences between these two types of wafers.

Epitaxial wafers are created through a process called epitaxy, which involves the deposition of a layer of single-crystal material onto a substrate wafer. This process is typically performed in a high-temperature, high-vacuum environment using techniques such as molecular beam epitaxy (MBE) or metal organic chemical vapor deposition (MOCVD). The resulting epitaxial layer has the same crystal structure and orientation as the substrate. Epitaxial wafers are a crucial component in the semiconductor industry, serving as the foundation for the production of high-quality electronic devices.

Thin film wafers, on the other hand, are created by depositing a thin layer of material onto a substrate wafer using techniques such as sputtering, chemical vapor deposition (CVD), or physical vapor deposition (PVD). Thin film wafers can be used to create a wide range of electronic devices, and are often used in applications such as photovoltaics, optical coatings, and MEMS (micro-electromechanical systems).

One of the main differences between epitaxial wafers and thin film wafers is the thickness of the deposited layer. Epitaxial wafers typically have a thickness of around 1-10 microns, while thin film wafers can have a thickness ranging from a few nanometers to several microns. Another difference is the crystal structure of the deposited layer - epitaxial layers have the same crystal structure and orientation as the substrate, while thin film layers can have a different crystal structure.

Overall, both epitaxial wafers and thin film wafers play important roles in the production of electronic devices. The choice of which type of wafer to use depends on the specific application requirements, such as the desired thickness and crystal structure of the deposited layer.

Epitaxial wafer and thin film manufacturers play a critical role in the production of these advanced semiconductor materials, utilizing state-of-the-art manufacturing techniques to ensure the highest level of quality and consistency. By working with us, companies can access a reliable source of epitaxial wafers and thin films that meet their strict performance requirements.

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com