GaN on Diamond Wafer

GaN on Diamond Wafer

Description

GaN on diamond wafers are a type of heterostructure material composed of a thin layer of gallium nitride (GaN) deposited on a diamond substrate. This type of wafer is typically fabricated using epitaxial techniques such as metalorganic chemical vapor deposition (MOCVD).

GaN on diamond wafers have unique electronic and thermal properties that make them suitable for various applications, such as high-power electronic devices, high-frequency transistors, and high-temperature sensors. The combination of GaN's high electron mobility and diamond's high thermal conductivity can result in devices that exhibit both high power and high efficiency.

We supply thermal grade polycrystalline diamond that can be used as an efficient heat sink to solve the heat dissipation issues in temperature sensitive devices, such as power devices, lasers and photodiodes etc. We also provide wafer form polished diamond substrates with sub-nanometer RMS surface roughness, which is suitable for the integration of GaN, Ga2O3 and AlN epilayers and devices on diamond via direct bonding or epitaxial growth.

Characteristics of CVD Diamond:

✔ Extreme hardness

✔ Ultra high thermal conductivity (1000-2000W/mK,a few times higher than copper)

✔ Wide optical transparency range

✔ Chemical inertness, not affected by acids or other chemicals

✔ Graphitization only at very high temperatures (T>700℃ in with oxygen content and 1500℃ in an inert atmosphere)

One of the primary advantages of GaN on diamond wafers is their high thermal conductivity, which allows them to dissipate heat more efficiently than traditional materials such as silicon or GaN. This property makes GaN on diamond wafers ideal for use in high-power devices such as RF power amplifiers and power electronics.

GaN on diamond wafers also have a wide bandgap, which allows them to operate at high temperatures without degradation. This makes them suitable for use in high-temperature sensors and electronic devices that need to operate in harsh environments.

We offer Diamond Thermal Management solutions

✔ Thermal conductivity for performance and cost requirements

✔ Custom sizes and shapes for specific applications

✔ Optical transparency any proper applications

✔ Bonding efficacy and layer performance

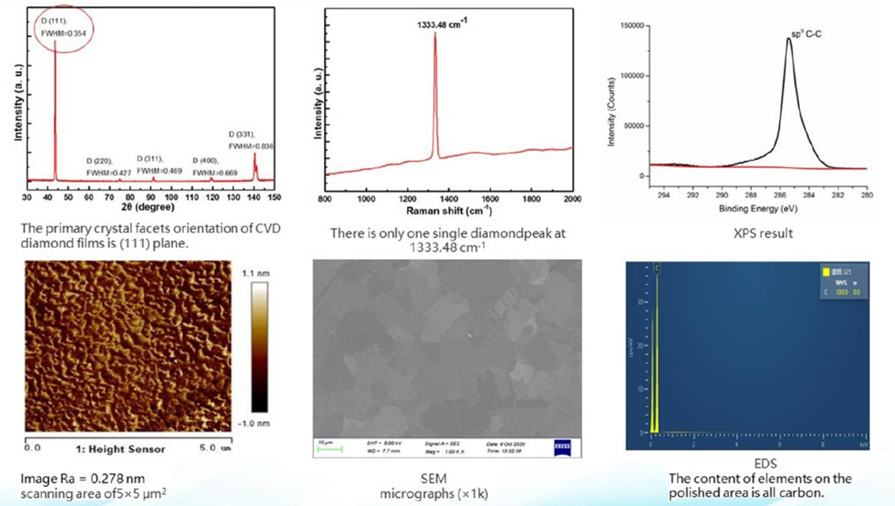

| Product name | Wafer level diamond (Dia 0.5) | Diamond heat sink (Dia 30) |

| Growth Method | MPCVD | MPCVD |

| Thickness | 0-500 um; customized | 0-500 um; customized |

| Thickness tolerance | ±20 um | ±20 um |

| Size | 2 inch; customized | 2 inch; customized |

| Roughness of growth surface (Ra) | <1nm | <30nm |

| FWNM (D111) | 0.354 | 0.354 |

| Coefficient of thermal expansion | 1.3(10·6K·1) | 1.3(10·6K·1) |

| Thermal conductivity (T.C) | 1000·2000W/m.K | 1000·2000W/m.K |

| TTV | ≤15μm | ≤15μm |

| Warp | ≤40μm | ≤40μm |

| Bow | ≤30μm | ≤30μm |

Order Form

About Semiconductor Electronics

SEMI EL project is a global supplier of materials, equipment, spare parts and supplies for the semiconductor industry.

Get In Touch

Email: info@semi-el.com